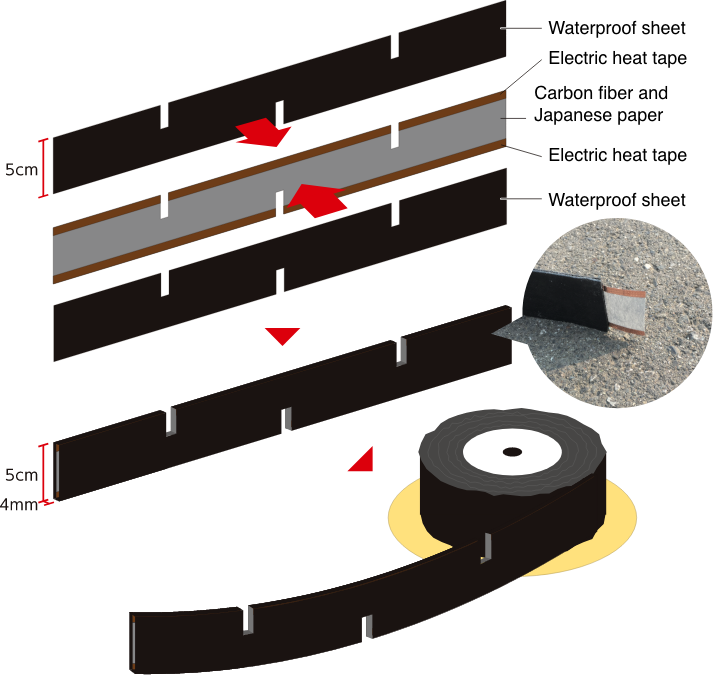

TAIYO SHEET structure

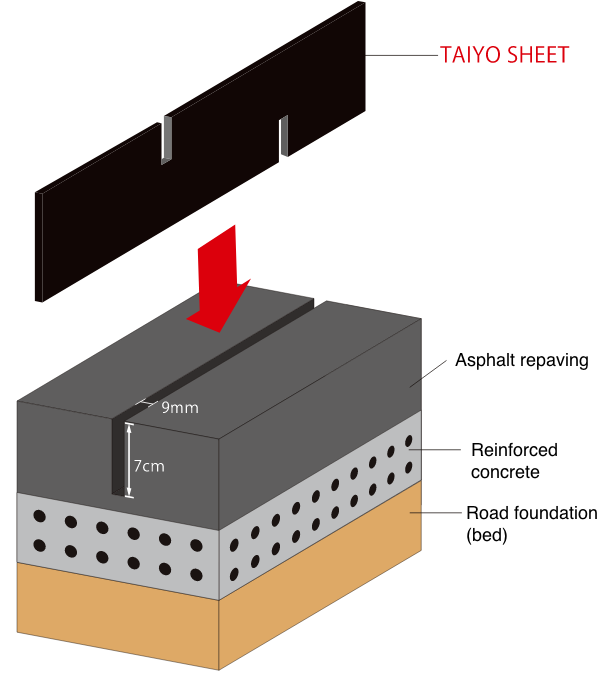

In the past, people deiced by tearing up pavement and embedding a heat source or piping in hot water. However, with TAIYO SHEET we just cut a 9mm groove and insert it.

No pavement needs to be torn up or pipes used, which keeps total costs low and greatly reduces road closure times.

Infrastructure plays a fundamental and vital role in all economies. Transportation infrastructure is indispensable. A variety of methods are taken today to remove snow and deice roads to ensure that products can still reach their end destination (the consumer) when roads are covered in snow.

There are snow plows to remove snow and deicing using salt and antifreeze agents, but both of these methods involve enormous costs. TAIYO SHEET boasts high performance on both initial and running costs.

- Sheet temperature zone

- 10~100℃

*Surface temperature zone varies depending on the environment.

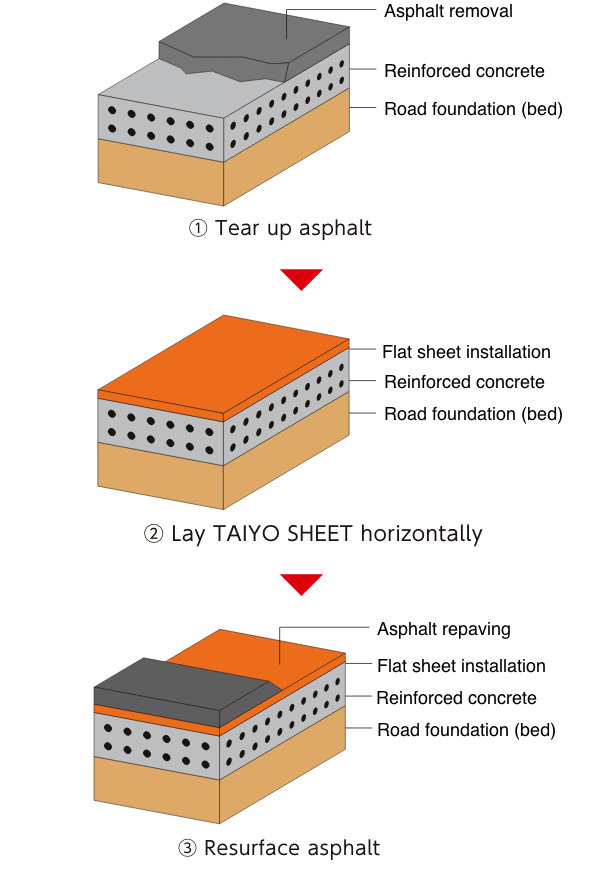

Processing of road heating

Until now, it has been necessary to tear up the asphalt, lay a horizontal thermal sheet, and then repave the asphalt. However, the innovative technique we have developed allows a TAIYO SHEET to be inserted vertically into a 9mm wide x 7cm deep groove cut into the asphalt. This innovative technique improves the total cost, installation time, and durability compared to previous methods.

Processing of

previous road heating

Simulation of

road heating with a new TAIYO SHEETWith TAIYO SHEET, a 9mm wide x 7cm deep groove is cut into the road, wherein the sheet is laid vertically.

Thus, there is no need to tear up asphalt over the entire surface of the road, and after-processing times are reduced, which can reduce installation times and costs.

Features of TAIYO SHEET

-

Feature 1

Low total costs

Because TAIYO SHEET does not require costs associated with the traditional method of tearing up asphalt and repaving the road, it can greatly reduce costs.

And considering this road heating can be used in 10-year increments, running costs also become extremely important. TAIYO SHEET boasts high performance on both initial and running costs.Initial costs (1m²)

-

Costs of

traditional methodsJPY 1,500to tear up the asphalt+

JPY 5,500

to repave it

–

-

Innovative

method:JPY 700

to cut asphalt

=

- Saves JPY 6,300/m²

Running costs (1m²)

-

Costs of

traditional method (reference):110W/m²

(per hour)

–

-

Costs of

innovative method (reference):60W/m²

(per hour)

=

- Saves 50W/m²

Traditionally, because the surface heating element was laid horizontally, it would work with only the top part heated. However, because the TAIYO SHEET is inserted vertically it can transmit heat to both the left and right sides, which reduces the area needed and thereby reduces running costs.

With roads: 60W/m With bridges: 100W/m -

-

Feature 2

Reduces installation time

Local roads and freeways are normally travelled on 24 hours a day, carrying tens of thousands of vehicles a day. Traffic control for even just a few hours can inconvenience hundreds or thousands of people. That is why it is vital to keep installation times as low as possible so as not to inconvenience travelers. The only installation time needed with our innovative method is essentially cutting the asphalt, which allows for extremely speedy installation and minimized traffic control times.

Meters per hour

-

Traditional

About 5m/hr.

–

-

Innovative method

About 50m/hr.

=

- Increases installation work rate by 45m/hr.

-

-

Feature 3

Highly durable

Unlike other road heating methods, TAIYO SHEET is extremely durable and requires no maintenance.

And unlike traditional methods, our innovative method lays the sheet vertically, which reduces the contact area with the road and vastly improves durability.

-

Connecting to a power source & electricity rates

-

coming soon

Case studies

048-863-8948

048-863-8948